News

Site Editor

Site

/uploads/image/68bfc75ce735e.png

Site

/uploads/image/68bfc75ce735e.png

Batwing Lighting Technology for Even Greenhouse Growth

Views: 82421

Author: Site Editor

Publish Time: 2025-12-06

Origin: Site

Introduction: In greenhouse supplemental lighting systems, the Photosynthetic Photon Flux Density (PPFD) value is often regarded as the core performance metric. However, the uniformity of Photosynthetically Active Radiation (PAR) distribution has a more significant impact on the economic viability and consistency of crop production. An uneven light field can lead to the following issues:

• Heterogeneous Plant Growth Response: Differences in light radiation received by plants in different areas of the canopy directly lead to variations in photosynthetic rate, morphogenesis, and biomass accumulation. This ultimately manifests as inconsistencies in plant height, stem thickness, flowering time, and fruit maturity, severely affecting batch harvesting and the percentage of marketable produce.

Low Light Energy Utilization Efficiency:A portion of the light radiation falls on non-photosynthetic tissues (such as stems, aisles, or the ground) or causes photoinhibition in areas of excessive local intensity, resulting in the waste of effective radiation. To compensate for low-light zones, systems often need to increase the overall PPFD setpoint or extend lighting duration, leading to unnecessary increases in energy costs.

• Increased Complexity in Environmental Control: Uneven distribution of light and heat can exacerbate microclimate gradients (e.g., temperature, humidity) within the greenhouse, posing challenges for uniform environmental regulation.

2. Technical Solution: Optical Principle and Implementation of Bat-Wing Distribution

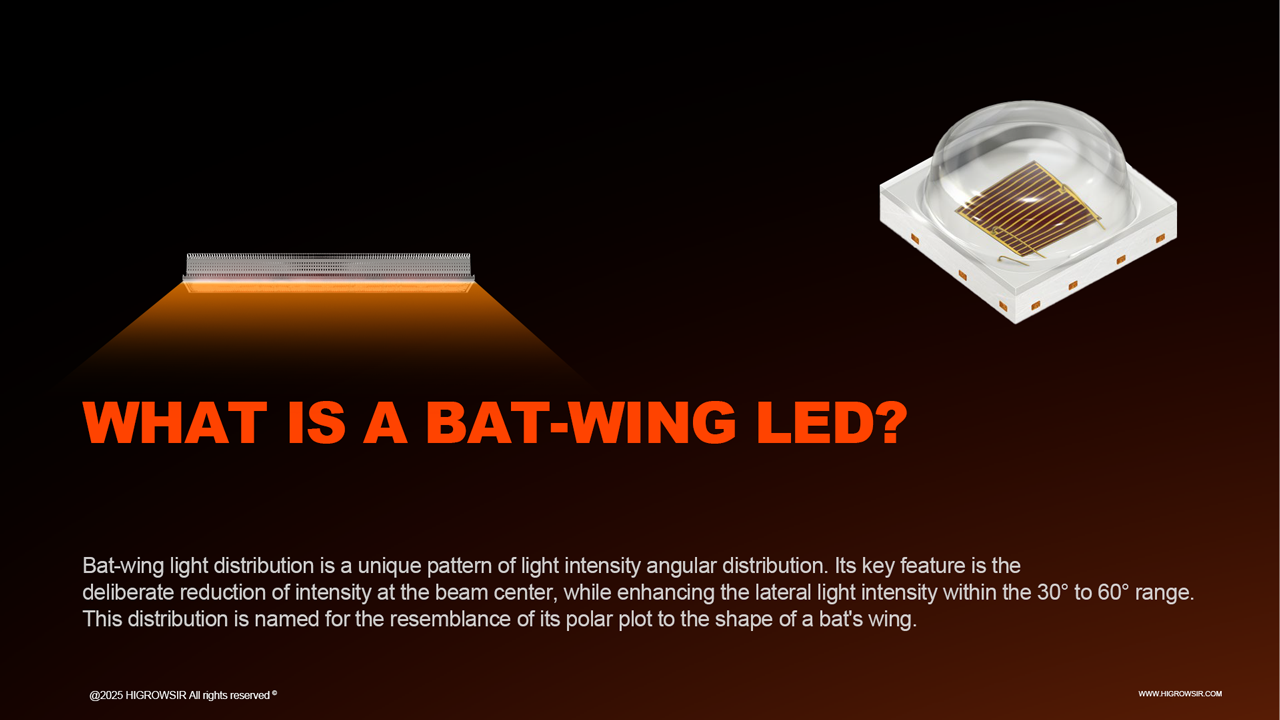

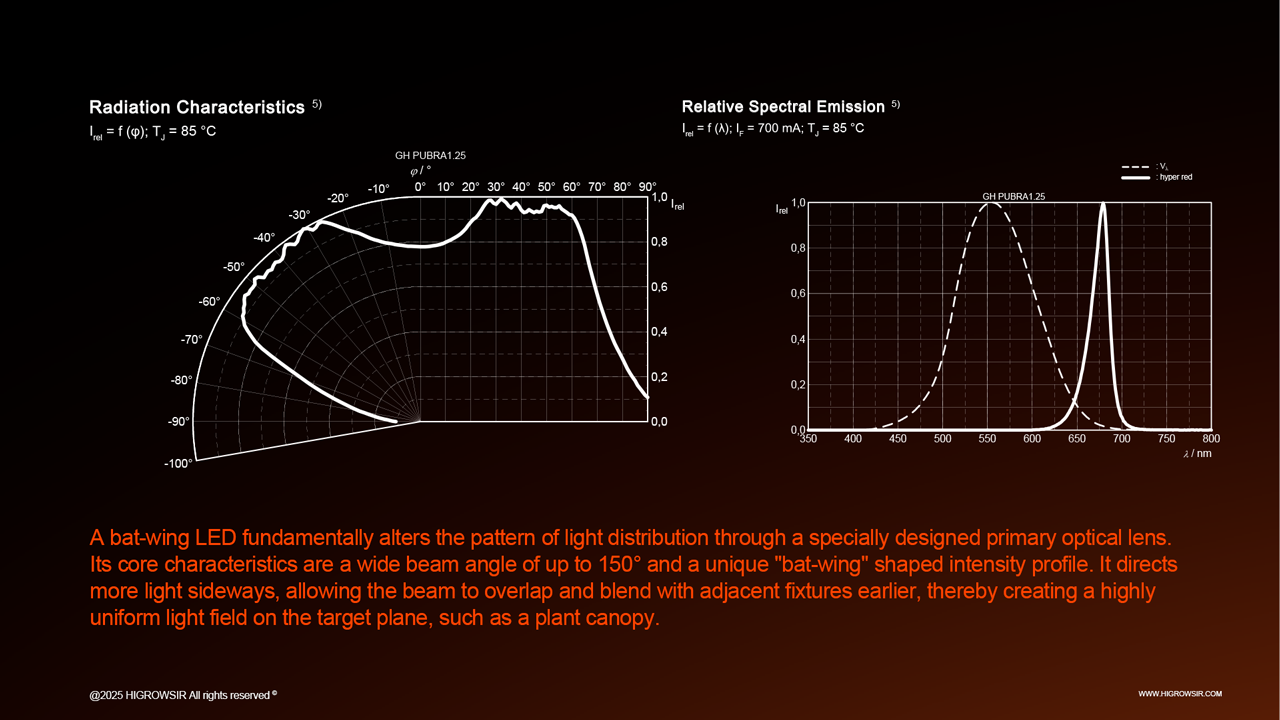

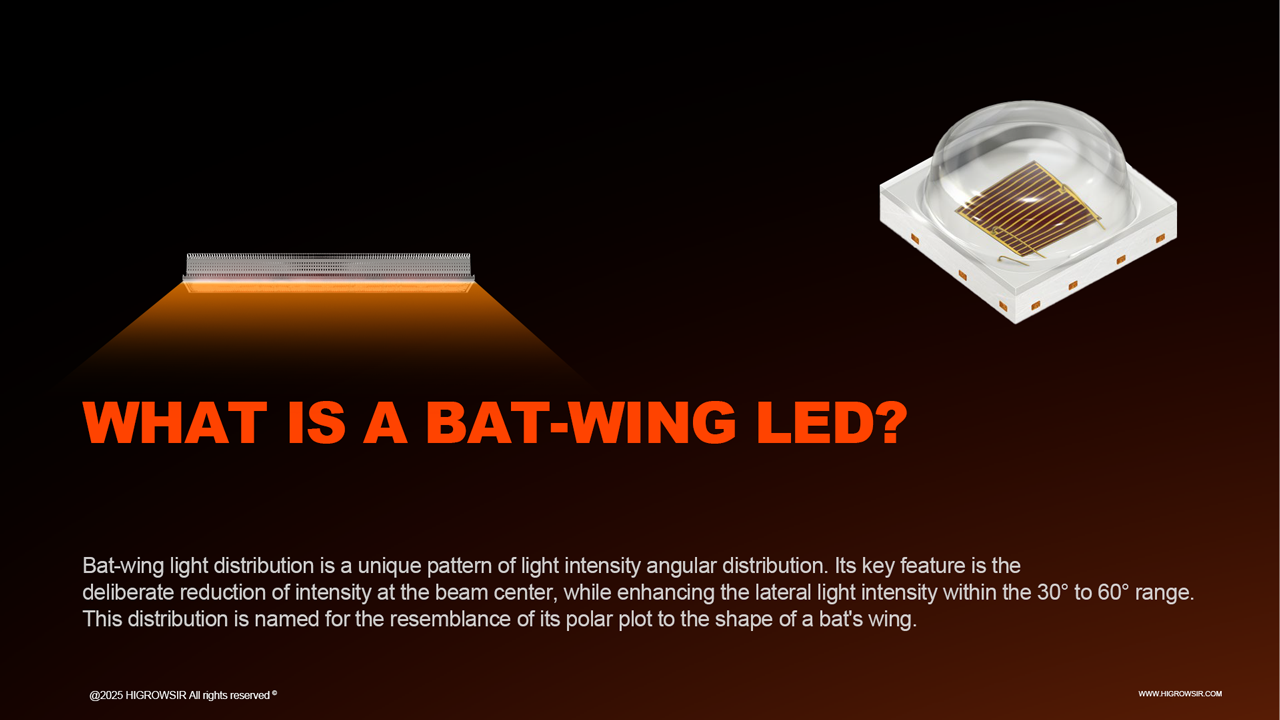

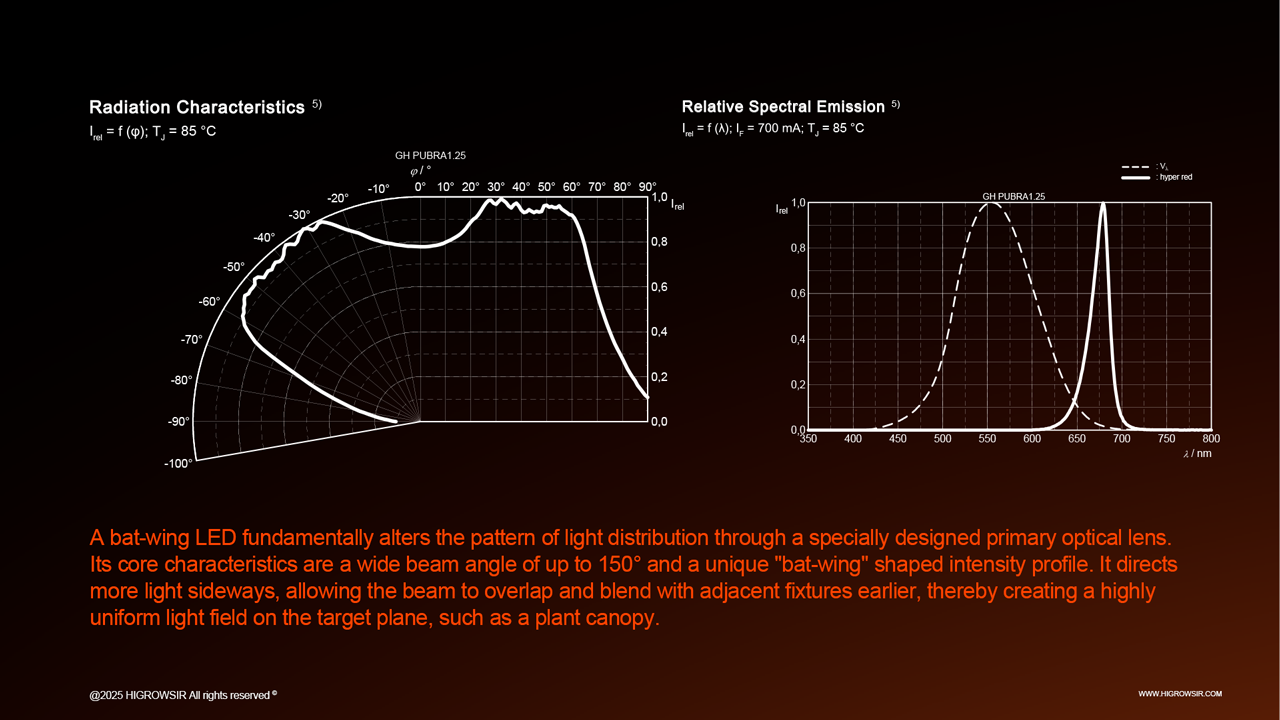

2.1 Definition of the Bat-Wing Light Distribution Curve

2.2 Uniformity Optimization Mechanism

This design optimizes the superposition of the light field within the illuminated area at a physical level by controlling the light emission direction:

-

Elimination of the Central Hotspot: Reduces the peak light intensity directly below the fixture (near 0°), preventing the formation of a PPFD "hotspot" at the center of a single fixture's projection area.

-

Promotion of Beam Mixing: Enhanced wide-angle light rays can intersect, overlap, and blend with beams from adjacent fixtures earlier in the horizontal space. This creates a smooth supplementary illumination in the traditional "dark zones" between fixtures.

-

Expansion of Effective Coverage: At a given mounting height, a single fixture can achieve a wider illumination area with more gradual light attenuation. This helps achieve a higher uniformity index while meeting the target average PPFD.

2.3 Systemic Engineering Implementation

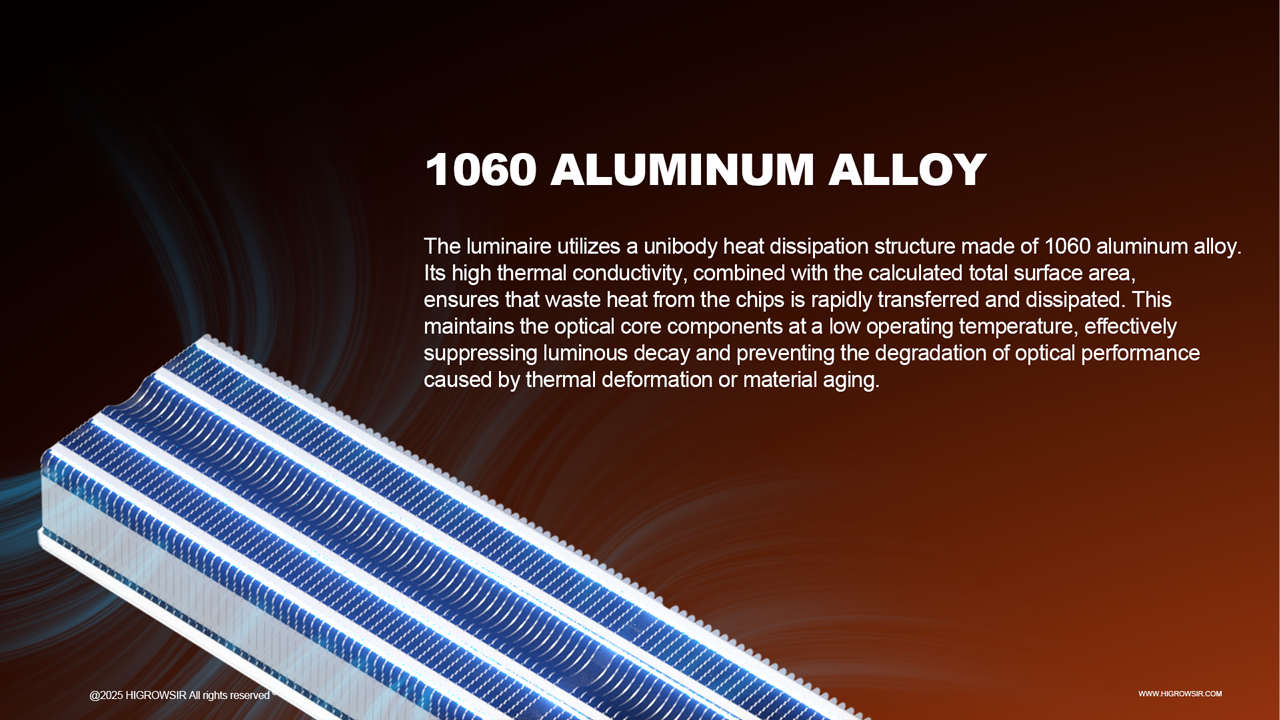

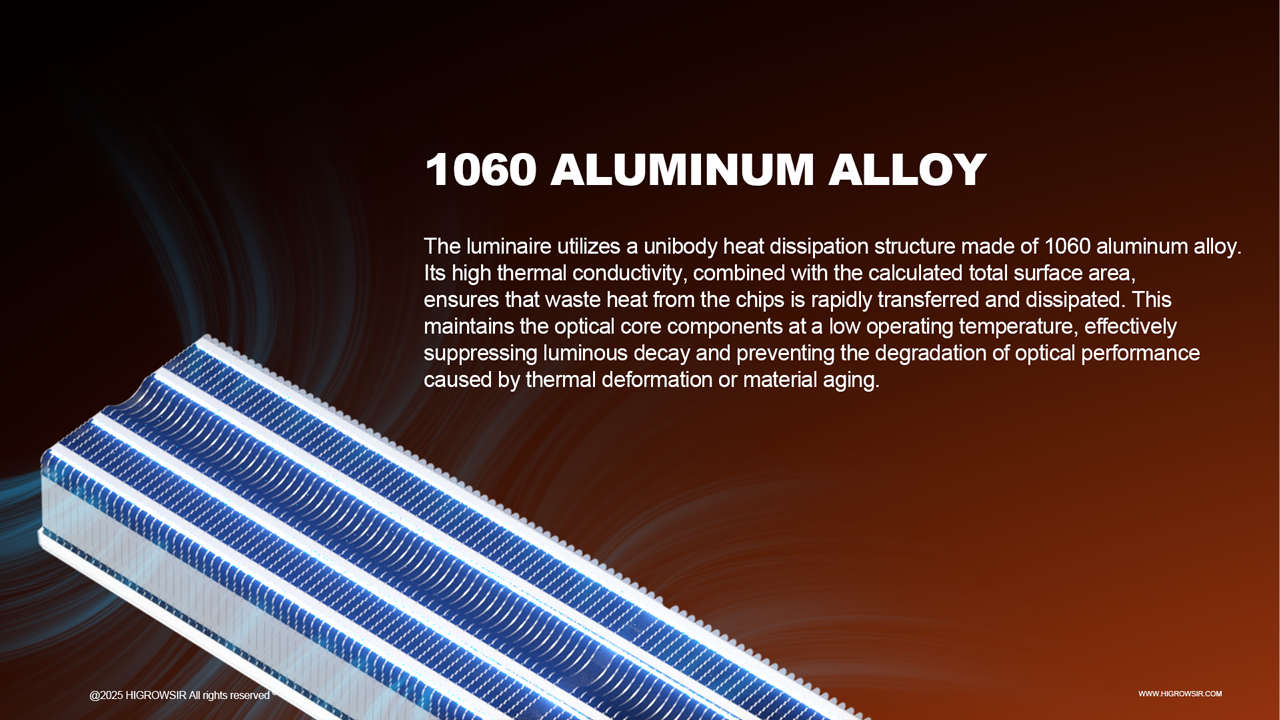

Thermal Management for Long-Term Stability: The optoelectronic performance and lifespan of LED chips, as well as the long-term stability of the optical lens, are sensitive to junction temperature. To maintain the consistency of the bat-wing light distribution characteristics over tens of thousands of hours of operation, the luminaire employs a unibody heat dissipation structure made of AL1060 aluminum alloy. Its high thermal conductivity, combined with the calculated total surface area, ensures rapid transfer and dissipation of waste heat generated by the chips. This maintains the optical core components at a low operating temperature, effectively suppressing luminous decay and preventing the degradation of optical performance caused by thermal deformation or material aging.

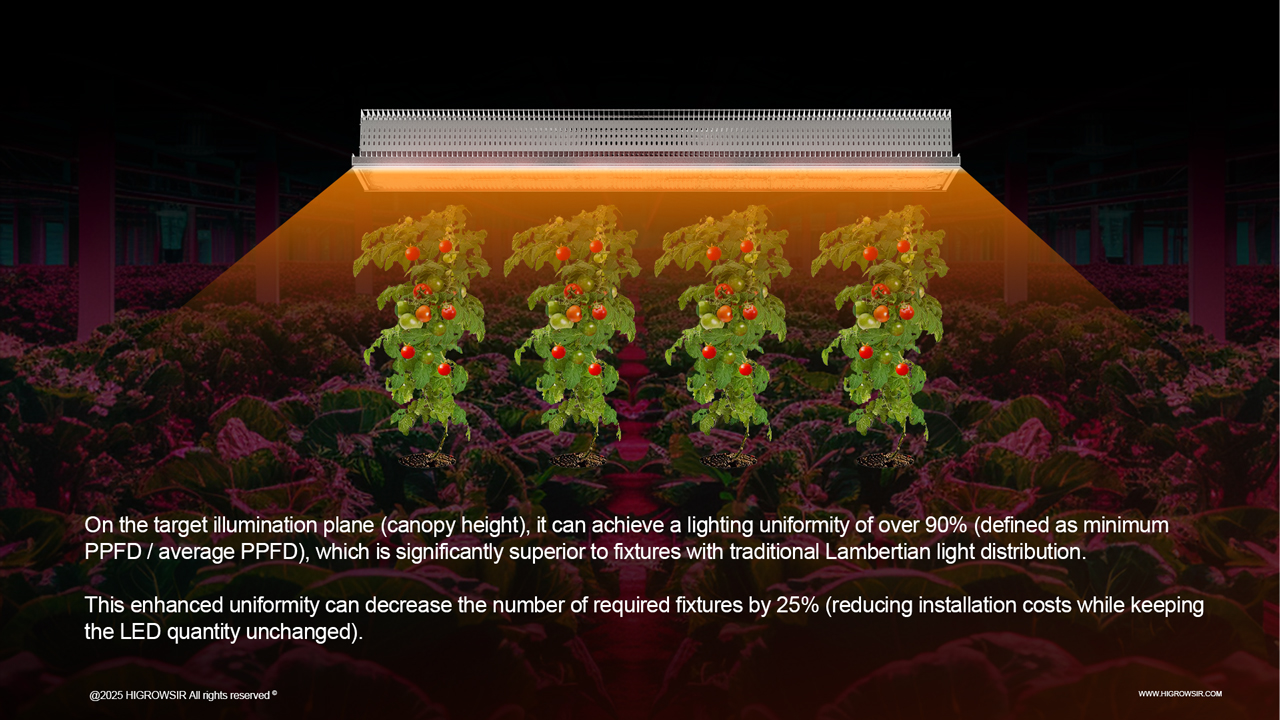

For commercial greenhouse operations, the value of a supplemental lighting system lies not only in its total light output capacity but even more critically in its ability to deliver light energy to the entire plant canopy efficiently, uniformly, and consistently. Grow lights based on bat-wing optical design represent an engineering philosophy shift from mere "illumination" to "precision lighting."

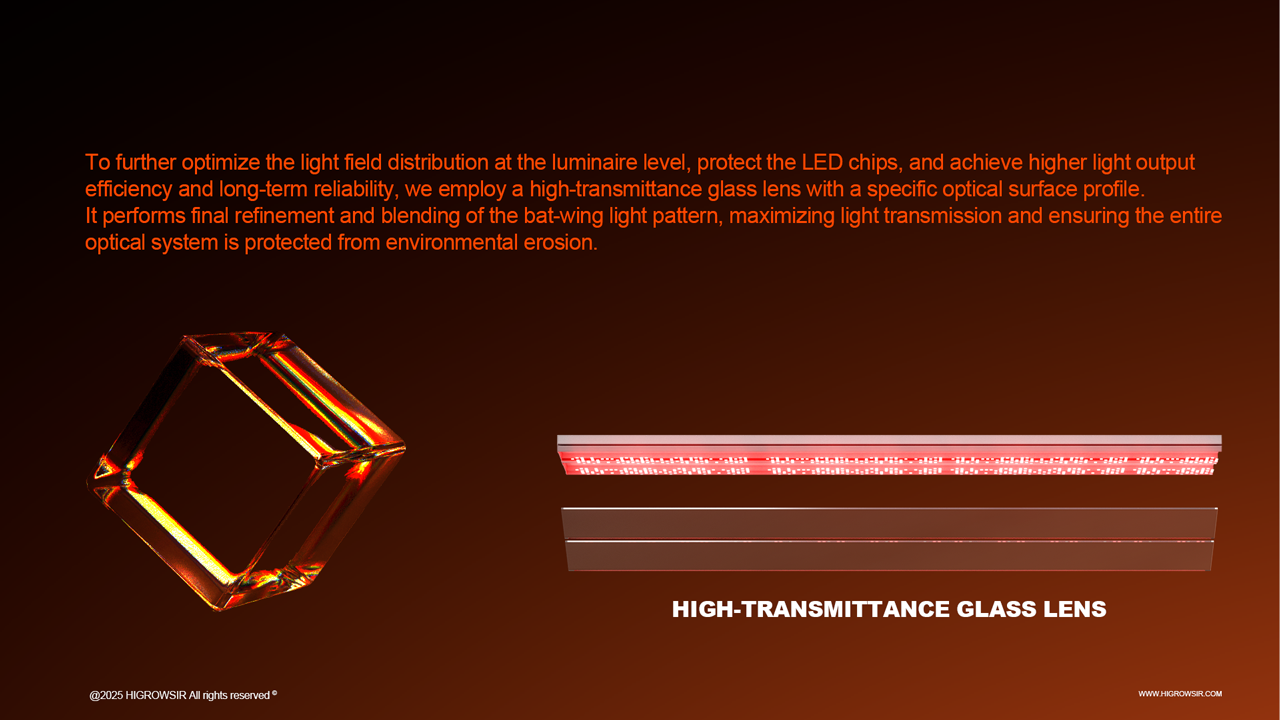

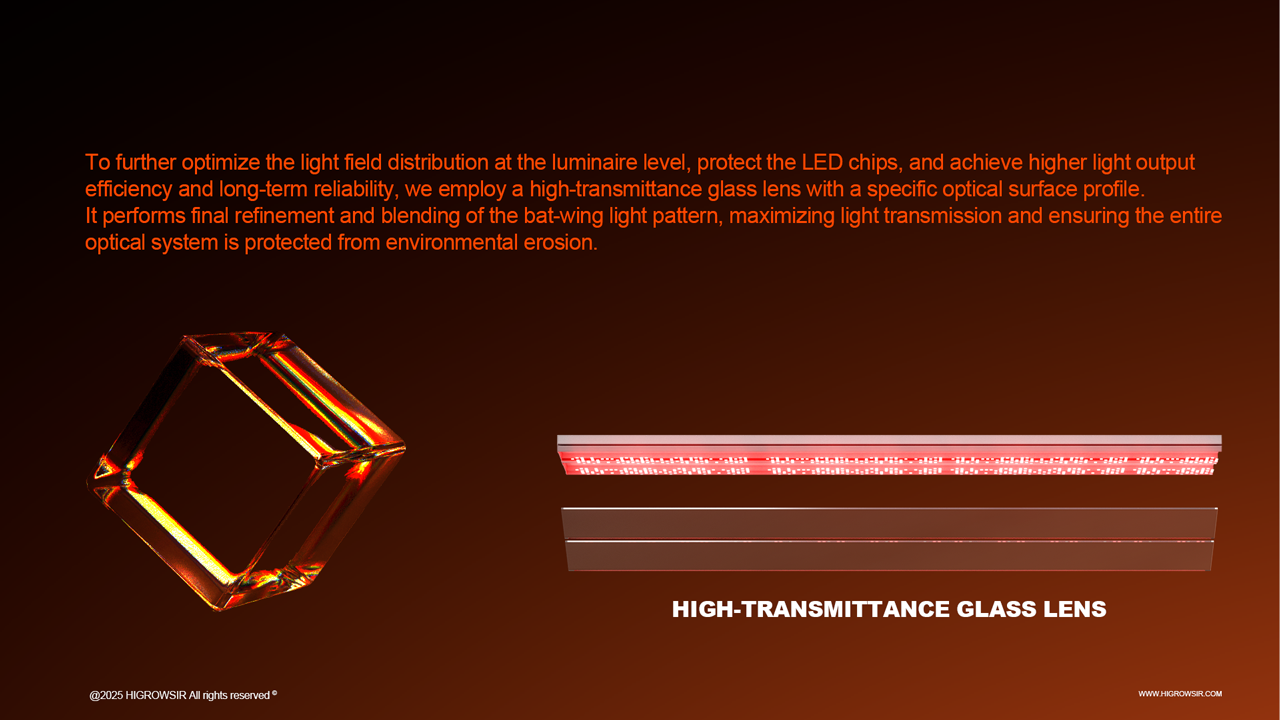

Through the integrated trinity of a high-thermal-conductivity frame (AL1060), a high-efficiency photon engine (OSRAM LEDs), and precision optics (custom glass lenses), this solution ensures the reliable, long-term achievement of uniform light distribution at its source. It provides growers with a vital technological tool for pursuing higher yields and quality, while simultaneously enabling refined energy management and standardization of production processes.

Follow-up Research and Application Support

We can provide a light distribution simulation report based on your specific greenhouse parameters (such as span, height, and cultivation trough layout) to quantitatively predict the uniformity improvement and energy-saving potential. Our technical team is ready to provide you with a customized analysis.